lithium process filter

l

Filters for Lithium Ion Battery Cell Manufacturing

Filtration and classification technology for improving battery quality and reducing cost

A variety of lithium (Li) ion batteries are used to power many different devices, from mobile phones to laptop or notebook computers. The quality of these batteries has improved over the years, giving rise to many new applications. Although we all rely on batteries in our daily lives, the market size remains under a billion USD. This is expected to change in the near future, with recent improvements that allow Li ion batteries to be used in the new Hybrid Vehicles (HV), Plug-in Hybrid Vehicles (PHV), and Electric Vehicles (EV). The market for these batteries is expected to double in size in five years. Until recently, Li ion batteries for cell phones and notebook PCs have been mainly manufactured in Japan, Korea and China.

However, US and European companies have now entered this market and started developing new batteries. Electric car and Li ion battery manufacturers have each announced plans for expanding production. In fact, the capacity for mass production of Li ion batteries for electric vehicles is expected to greatly increase over the next four years. Product quality and cost are foreseeable concerns. Batteries for electric cars have more stringent requirements for performance and safety than those for small devices. Pall’s filtration products improve the manufacturing process of Li ion batteries, helping to reduce operating costs.

Placement and benefits of Pall filters in Li ion battery cell manufacturing processes

Filtration in the electrode manufacturing process

A lithium ion battery is primarily comprised of electrodes (cathode and anode), separators and an electrolyte solution. The manufacturing process, which is outlined in Figure 1, involves forming the electrodes, stacking the cells, adding the electrolyte solution, charging the battery, aging and final inspection. Pall filtration recommendations are indicated in this schematic. Filtration has been found to significantly improve battery quality

and performance. Proper filter selection is required to remove particulate contaminants and gels from solvents, water and the high viscosity slurries used in forming the electrodes. Filters are also needed to remove particle contamination during the electrolyte filling process. Since the presence of water is detrimental to the electrolyte solution, it is recommended that the carrier gas be passed through a Pall purifier to reduce moisture levels to <1 ppb.

As indicated in Figure 1, there are two basic steps involved in the formation of the electrodes: mixing of the slurry ingredients and coating of the slurry onto the substrate. Filtration can greatly improve these operations.

Removal of metal ions from solvents and DI water The active materials used to make the cathode and anode electrodes are different, but each is suspended in solvents or water containing binder powder. Solvents and water are typically transported from facilities through metal piping. The pipes may release particles and metal ions that can contaminate these liquids and affect battery quality. These ions can be effectively captured by membrane purifiers. The Pall IonKleen™ membrane purifier consists of

a micro-porous, ultrahigh-molecular-weight polyethylene substrate with covalently bonded, strong acid cation exchange groups. Configured as a standard cartridge or capsule (see Figure 2), the IonKleen purifier has a very large effective surface area but a small footprint, enabling it to be placed right at or close to the point-of use. Pall IonKleen purifiers are highly efficient because they do not rely on slow diffusion into a resin bead to achieve ionic adsorption. Rather, due to the intimate contact of the solvent or water with the densely packed ion exchange groups on the membrane, rapid kinetics occur with immediate and spontaneous removal of the trace contaminants. Trace ppb levels of cations can be reduced to ppt levels. This is schematically depicted in Figure 3.

Reduction of gels and particle contamination in electrode slurries During the manufacturing of electrode slurries, filtration is highly recommended at the following points in the process: • during the mixing of the slurry components to remove extraneous particles and undissolved gels • immediately before die coating the slurry onto the electrode substrate In the latter step, filtration is required to remove aggregated slurry particles and reformed gelatinous material to protect the narrow space between coater and substrate. Filtration can also remove oversized particles, creating a narrow slurry size distribution. This results in a more even coating, as illustrated in Figure 4.

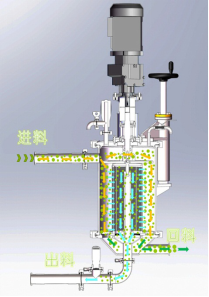

The principle mechanism of the Automatic Mechanical Arm Backwash Filter is that of a mechanical scraping cleaning action. The fluid flow is from outer to inner for both the filtering cycle as well as the backwash cycle. The impurities, over a period of usage, clog the filter element slots gradually reducing the filtrate throughput and increasing the pressure drop across the filter element. After the stated allowable pressure drop is reached, the differential pressure switch signal actuates the rotation of the filter element. The automation is governed by the logic control on the control panel. Thus begins the backwash (cleaning) cycle. During the backwash cycle, due to the scraping action of the stationary mechanical arm, the impurities clogging the filter element are dislodged. Thus, an effective clean-in-place solution for clogged filter element is achieved. A key feature of this model is that the filtering cycle is simultaneous with the backwash cycle i.e. online backwashing hence there is no interruption of flow.