lithium process filter

Shanghai hengfilter Industrial Equipment Co., Ltd. is located in Jinqiao, Pudong New Area, Shanghai. The company is a comprehensive enterprise specializing in research, development, production and sales of filter equipment. Most of its business and technical personnel come from international mainstream filter equipment manufacturers, with a strong international vision Shanghai constant filtration constant filtration equipment Co., Ltd., based on European and American technology, is a professional manufacturer and service provider specialized in transportation, filtration separation and control system in the field of industrial fluid. Constant filtration provides a one-stop solution from auxiliary filtration to residual liquid recovery

Shanghai constant Filtration System Co., Ltd. is a professional filtration company, dedicated to providing customers with full professional filtration support. Our company can provide a full range of filtration solutions in the field of lithium battery, and can provide customers with transformation services of filtration syste1. Upstream coating material filtration, homogenization and pulping filtration services It provides positive, negative, transfer coating and extrusion coating. Different from other filter manufacturers, Shanghai hengfilter Co., Ltd. is a customized solution, i.e. positive, negative, extrusion coating and transfer coating. It provides different solutions according to the material properties2. Downstream electrolytic copper and lithium salt filtration 3. Electrolyte, manganese sulfate

4. Graphite dust, graphite asphalt filtration

5. Washing and pressure filtration of positive material, lithium iron phosphate, ternary

6, Strong magnetic iron remover

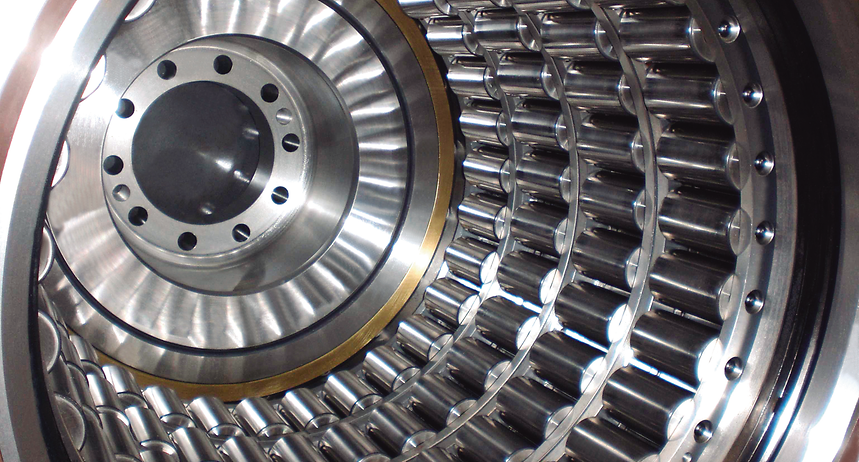

Lithium coating slurry filtration: Technical features: 1. Different from the vertical motor, the horizontal motor only needs one coupling to reduce the eccentricity in the operation process, avoid uneven eccentric force on the scraper, and wear the filter screen

2. The bottom is designed with heavy impurity deposition tank, which can greatly reduce the friction between large hard particles and scraper, resulting in screen wear 3. Buffer structure design to prevent pressure jump 4, 2205 dual phase steel filter screen, imported filter screen, laser secondary cutting at welding position, no residue Coating slurry filter