candle filter

烛式过滤器

Products description:

In order to reduce the pollution caused by the open filter, and improve the dryness of the filter cake. We develop the closed candle filter.

Those pipes set up inside the filter is functional in different situation. Our candle filer is able to cope with many filtration applications, This is no driving equipment and it’s a simple mechanism. This filer can work automatically without any leakage.

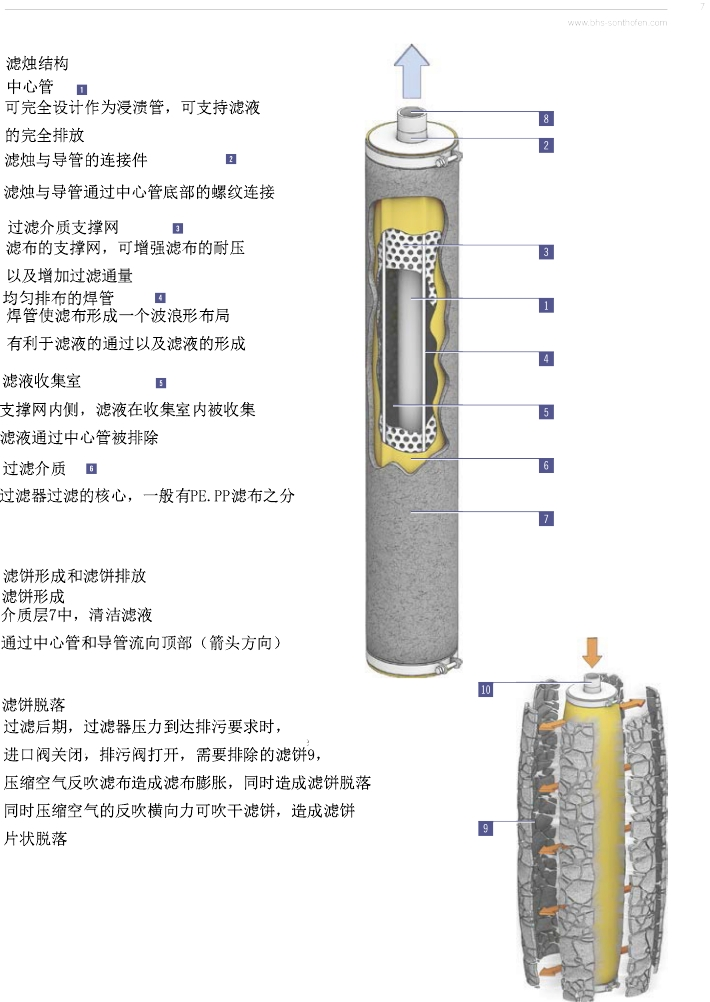

This candle filter is designed in a compound quincunx and row pipe(stainless steel inside,filter cloth outside), the drain pipe in-middle can help drain the liquid kept in the filter pipe, when slag is discharged, the gas is used to blow back, the efficiency is much higher than other filters. This filter can be used in those materials with the impurity content from 0.1% to 50%.

Operating principle:

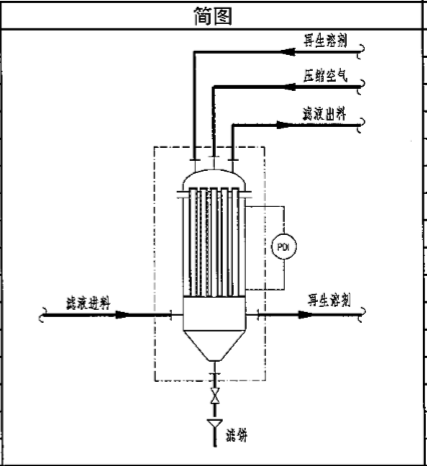

When the candle filter works, the materials will be send into the filter through the pump, the liquid in the materials will get into the center of the element after the filtering medium, gathering in the purified outlet, then discharged. Before the filter cake formed, the “purified liquid”can be filtered periodically, until the filter cake formed(can meet the filtration requirements), the the signal will be send to stop the circle operation, the purified liquid go to the next normal filter process through the valve.

After normal filtration for a period time, the filter cake reaches a certain thickness, feed charge door closed automatically, after the slag discharged completely, signal will be send by the system to blow back the gas to make the filter cake fall off. After blow-back, slag discharge outlet will be open to start deslagging. Outlet will be closed after going through this whole process. Then return to its initial state, ready for next filtration

Application:

Biopharmaceuticals: fermentation extracts, antibiotics, anti-cantharidin, streptomyces, citric acid

Chemical industry: Amine, Catalyst Recovery, Sulfuric Acid, Polyols, Titanium Dioxide, PTA Particles, Polyglycol, Potassium Carbonate

Food and beverage: Apple juice, grape juice, raw syrup, fruit grape syrup, glucose syrup, sucrose, beer, olive oil, palm oil, soybean oil

Metal processing:Cleaning agents, coal tar, machine cooling oil, sheet metal foil rolling oil

操作方法 | 间歇工作 |

操作压力 | 可达10 bar (g) |

操作温度 | 高达250°C |

固体含量 | 高达10% (wt.) |

滤饼厚度 | 高达30 mm |

过滤精度 | 0.5 µm 到以上 |

过滤面积-流量 | 0.1 to 10 m³/m² h |

滤渣含水率 | – |

设备过滤面积 | 1 to 150 m² |

candle filter is a batch-operated filter with candle�shaped filter elements arranged vertically inside a pressure vessel. The filter cake is formed on the outside of the filter candles while the clear filtrate is discharged from the interior of the candles through dip pipes. All the process steps are carried out under pressure. The candle filter is used for clarifying liquids with a low solids content. It is a compact unit, operates fully automatically and allows high throughput rates, dry cake discharge and a wide range of cake treatment options.

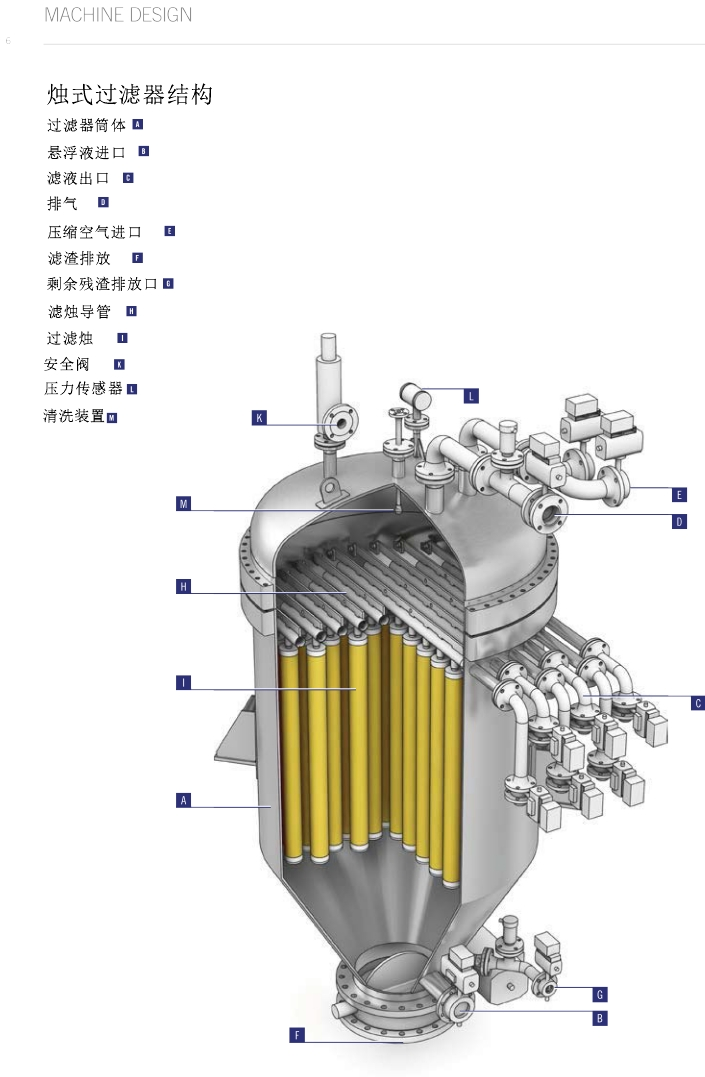

过滤器结构

High process versatility A variety of options are available for treating the filter cake, enabling the individual process requirements to be met. The cake can be washed or reslurried in one or more stages. Air, nitrogen or other gases can be passed through the filter cake to achieve a greater degree of dewatering. If required, precoat filtration by means of filter aids is possible. Fully automatic operation The candle filter operates fully automatically. On completion of a process cycle, the filter cake is separated from the candle surface by backblowing and subsequently discharged. The next cycle then begins. Safe pressure filtration system The entire filtration process takes place under pressure – up to a pressure differential of 10 bar g – in a closed, gas-tight system. This enables a BHS candle filter to be implemented even where strict health and safety regulations apply. It is also possible for products to be processed in an inerted or sterile environment. No moving parts The BHS candle filter does not incorporate any moving parts. This increases operational reliability and reduces maintenance requirements. Where cake discharge is concerned, the special surface configuration of each candle ensures that the cake is completely removed and discharged downwards.

过滤原理:

Heel filtration device The heel filtration device enables the residual volume to be processed on completion of the filtration cycle by means of an internally filtering candle at the vessel cone. This ensures complete heel filtration with a minimum of compressed gas. CIP system A CIP system is available for cleaning the filter interior, the register pipes and the filter candles. A special design of the candle filter with appropriate surfaces allows dependable cleaning of all parts in contact with the product. Precoat or body feed A precoat or a body feet plant is used to suspend powdery filter aid. The precoat plant operates in batch mode, whereas the body feed plant runs continuously. They are of modular design and comprise a storage tank, agitator, piping, fittings, measuring instruments, steel structure and pumps. Tube sheet design for slurry discharge In the case of slurry discharge, the candles are mounted on a tube sheet that separates the filtrate and suspension chambers. The filter cake is discharged by backflush with filtrate. Under specific conditions, the tube sheet design represents a cost�effective solution. Further accessories BHS has the experience to integrate additional accessories into the candle filter packages as required by the application, e.g. polishing filters or activated carbon filters.