cyclone separator centrifugal

Applications:

• Nozzle protection

• Mechanical seal protection

• Protection of heat exchanger surfaces to increase efficiency

• Removal of sand and grit prior to cooling tower basins and to prevent the fouling of heat exchanger tubes

• Pre-filtration for bag, cartridge, screen, disc, sand media filters, and centrifuges • Intake water liquid particle separation (river water, lakes, wells)

• Sludge removal from industrial wastewater • Recycling of solvents used in painting, machining, and other industrial processes

• Machine tool coolant filtration to extend coolant and tool life • Steel mills - cleaning, quench, and wash water

• Particle removal in oil and gas extraction and production

• Filtration of hot oil in food processing plants to protect heat exchangers

• Market segments - industrial, commercial/HVAC, municipal, irrigation, food, oil and gas

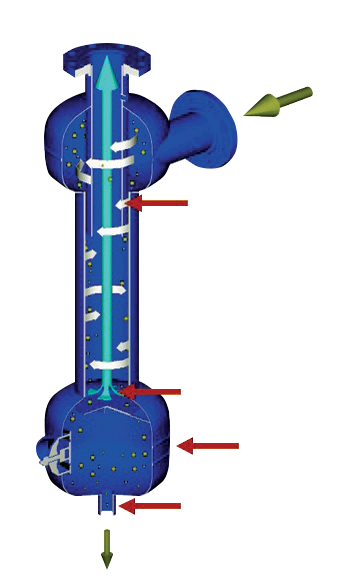

How it works 1. Particles enter the unit via the tangential inlet (1), driving circular flow within the separator. 2. Liquid velocity is increased by the internal acceleration barrel (2). 3. Particles are separated from the liquid by the centrifugal action caused by the circular flow in the unit. 4. Fluid from which the separable solids have been removed is drawn to the center of the vortex. The Vor-plate (3) enhances particle separation efficiency and controls liquid turbulence. Liquid from which the separable particles have been removed is drawn to the center of the circling liquid (vortex) and driven up an internal pipe feeding to the outlet. 5. The clean liquid exits the unit at the top via the outlet (4). 6. The separated particles are concentrated in the collection chamber (5) and removed through the purg