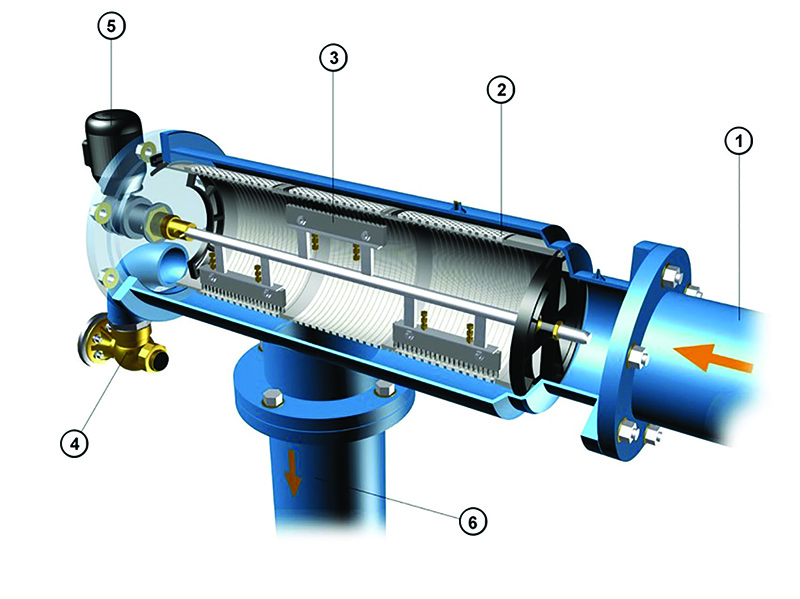

Auto back wash filter

brush filter is an electrically driven automatically self-cleaning filter. The function of the filter is controlled by a flushing controller. The cleaning process can be activated both automatically and manually. The self-cleaning system makes it possible for the filter cake that has formed on the filter screen to be brushed off, and a great deal of dirt can be removed without interrupting filtration. The short cleaning time of 16-20 seconds, using a minimum of flushing water, is sufficient to clean the entire filter element, with the filtering process being maintained. The main feature of this unique design is the self-adjusting brushes driven by the electric motor over the entire surface of the filter screen. Efficient cleaning is achieved by the perfect contact between the self-adjusting brushes and the screen surface. A wide range of Stablefilter Automatic Self-Cleaning Brush Filters is available for very broad application. The filters are available from 4" to 14" (DN 100 mm – 350 mm) with a capacity of up to 1,000 m³/h. The corresponding filter surface varies from 3,500 to 10,400 cm². The working pressure is 1 to 8 bar. Coating: In preparation for the coating, the filters are provided with a special layer of zinc phosphate. This treatment ensures proper adhesion of the coating, and protects against rusting-through from the inside. Subsequently, the polyester coating is applied electrostatically, both internally and externally, before being furnace�hardened. The entire process involves 7 steps, and results in a perfect coating with a thickness of approximately 120 microns. Applications: • Process water • Cooling water processes • Industrial waste water • Recirculation systems • Irrigation sy

Technical specifications: • Max pressure: 10 bar •

Min flushing pressure: 1 bar

• Ph 5 - 9 resistent

Materialen: • Filter body: polyester-coated steel (option: stainless steel)

• Rubbers: natural rubber NR (other materials upon request)

• Filter element: PVC element with stainless steel filter screen (Option: stainless steel perforated cylinder)

• Perforation: 3000 - 1500 - 800 - 400 - 200 microns